CNC multi-spindle machine MS40C: The standard to beat!

A machine concept that meets all requirements and the highest demands.

Machine highlights

Your benefits

-

Highly-dynamic slides with sliding guide (X-axis)

-

Non-wearing Z-axis due to quills with hydrodynamic support

-

Front-opening machine for bar machining

-

Chuck part machining with loading and unloading by robots or linear handling units

-

Swing arm is locked by three-piece Hirth coupling in machining position, ensuring maximum rigidity

-

Maximum of 6 tools for rear end machining per swiveling synchronous spindle

-

Already included: the operating systemXpanel i4.0 readywith 18.5” touch screen and INDEXC200-4D based on Siemens S840D sl

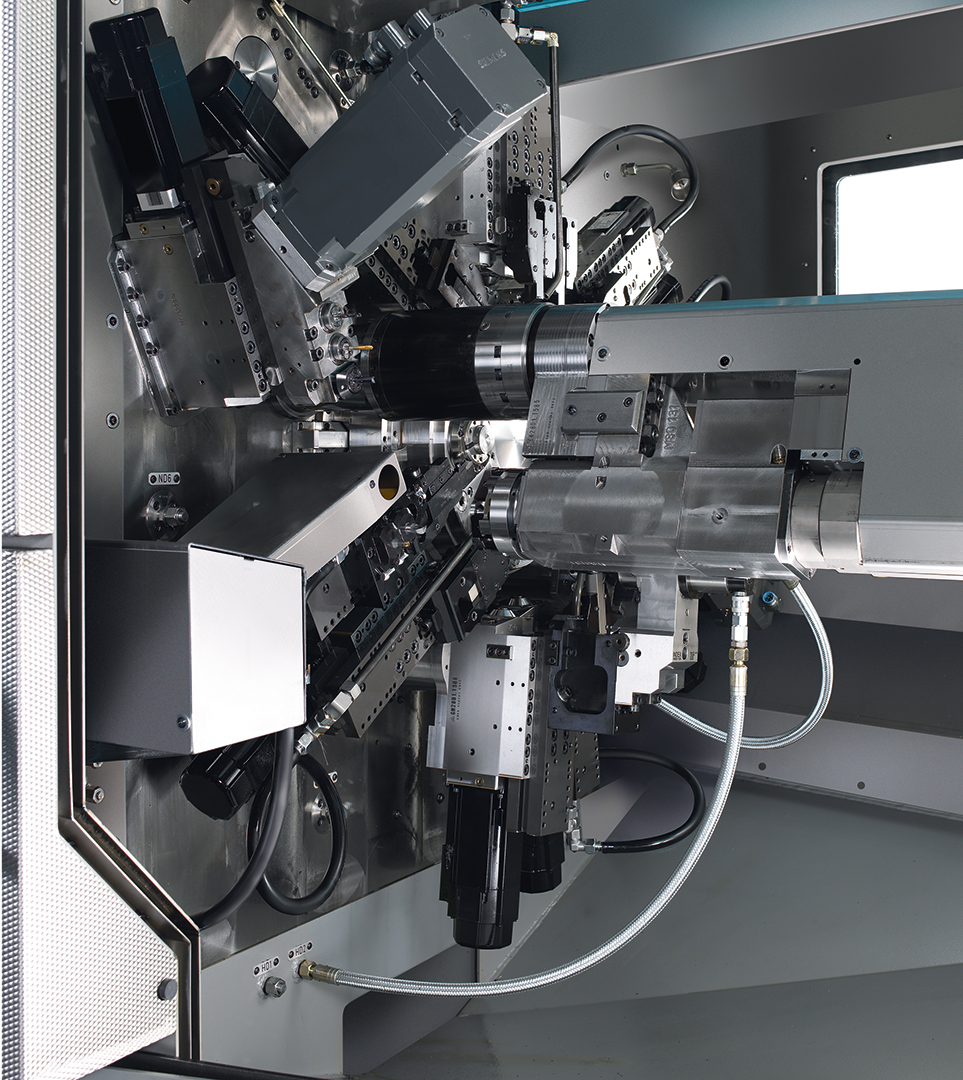

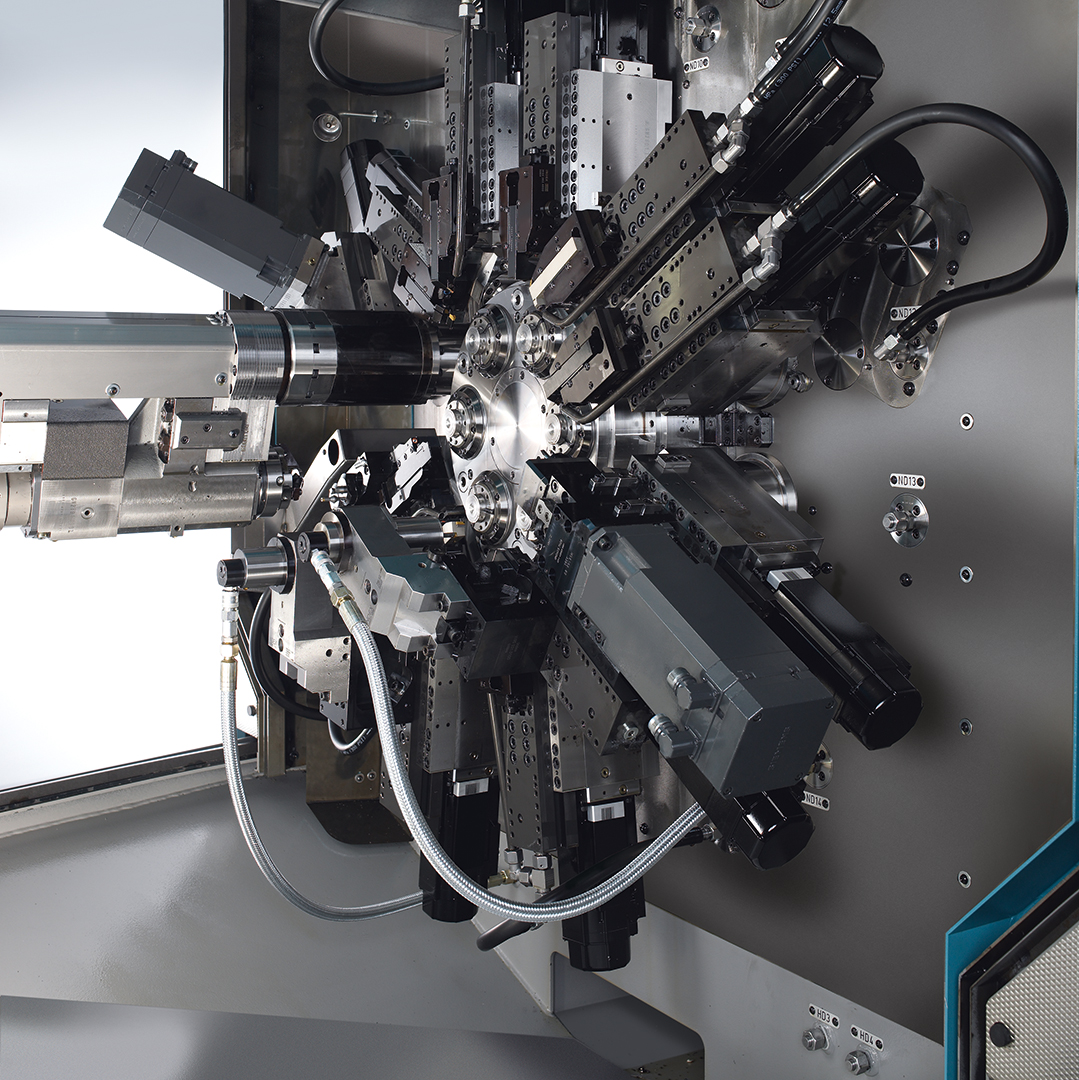

MS40C in focus

The machine design

-

Up to 6 tools, of which 2 are live

-

Fast swiveling motion and hydraulic locking of the swiveling synchronous spindle via a Hirth coupling

-

Favorable chip flow due to machining outside the main working area

-

Numerous possibilities using live tools in conjunction with C- and Y-axes as well as an electronic shaft