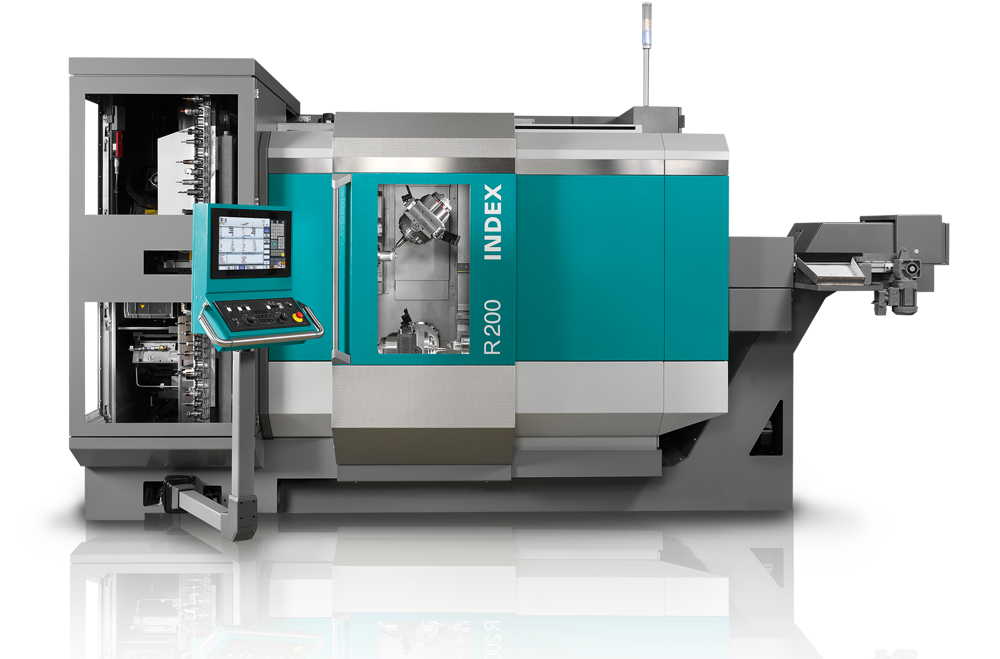

Turn-mill centers overview

INDEX turn-mill centers set the standard for economic, high-precision solutions tailored to the customer’s needs. Standards ranging from the classic production turning machine to tailor-made machining cells equipped with handling units. For the machining of simple to highly complex parts, in small to large lot sizes, INDEX consistently offers economically and technologically superior solutions.

Please choose your favorite turn-mill center.

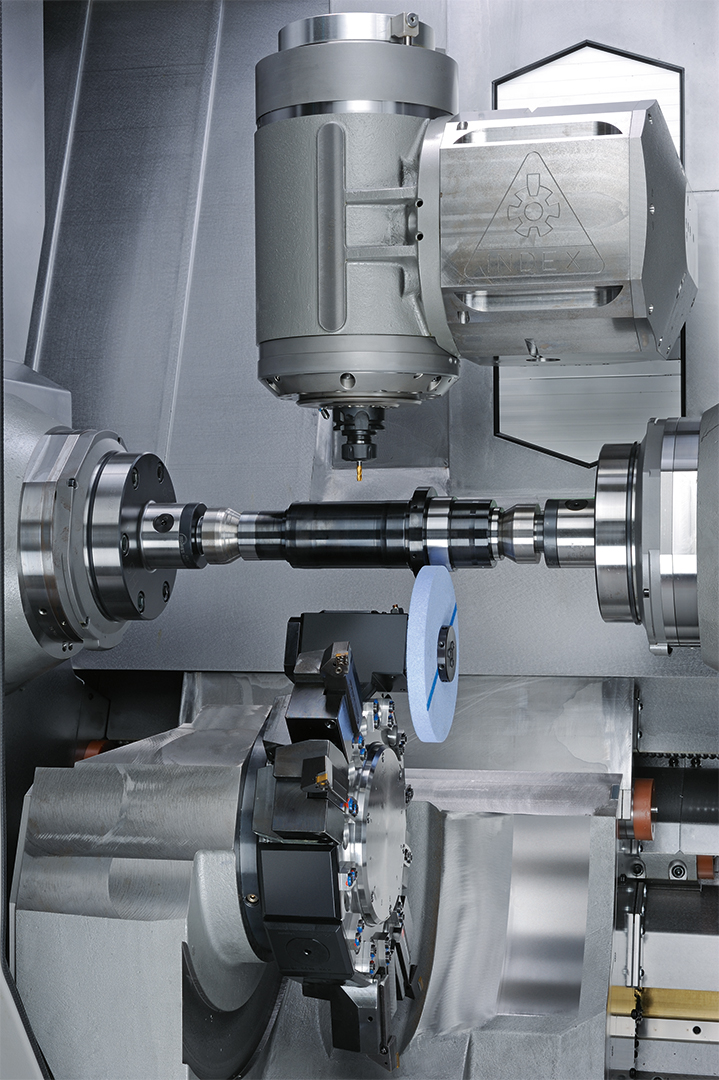

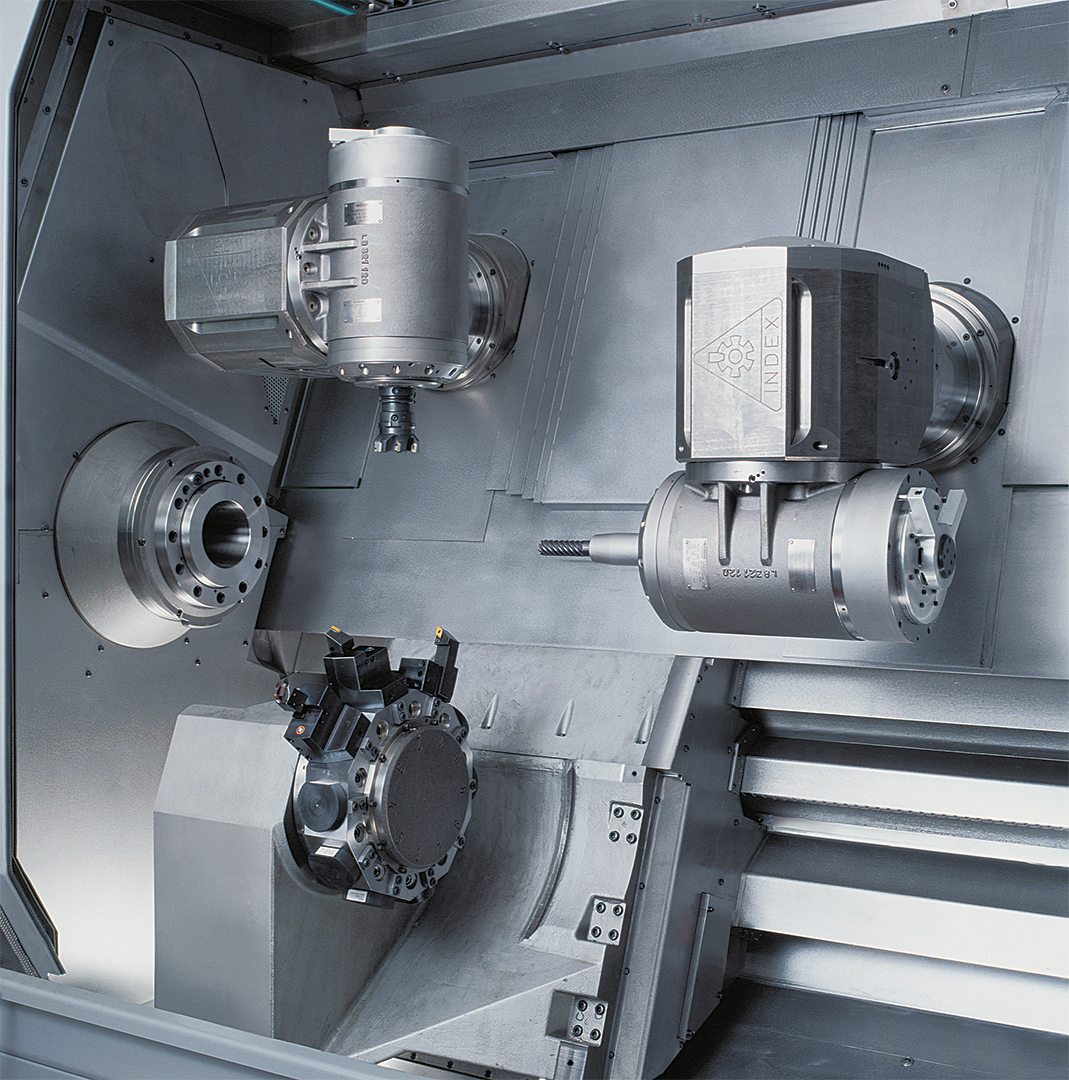

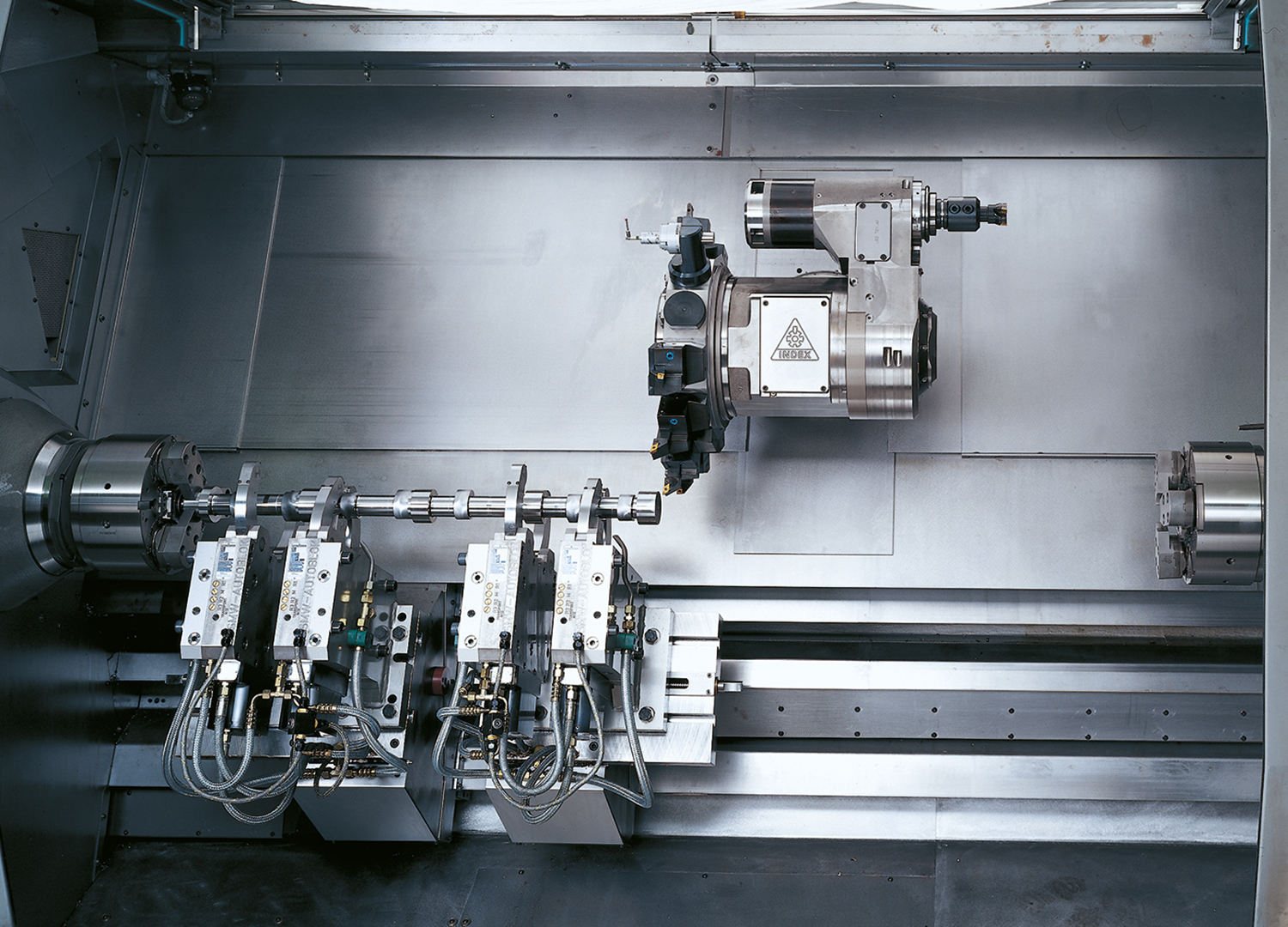

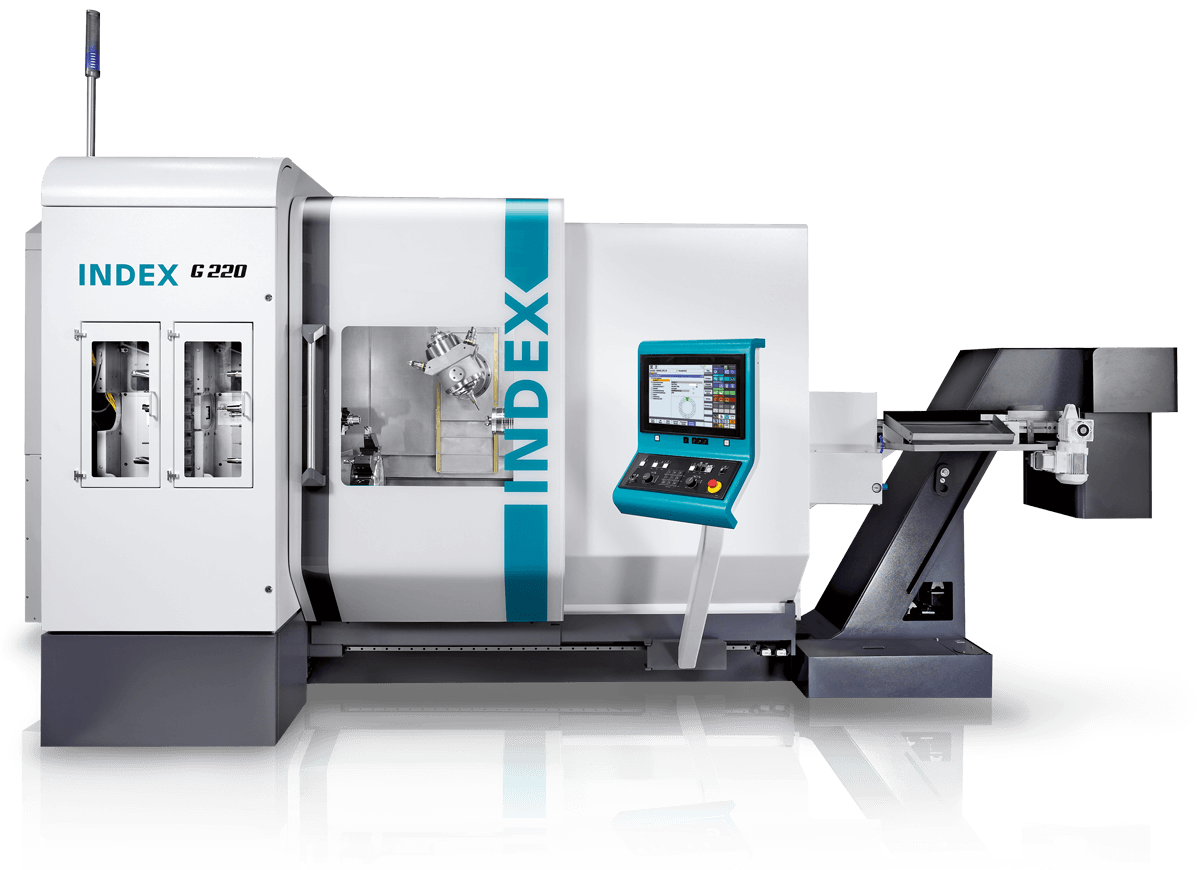

Generous work area designed for turning/milling or milling/turning

Generous work area designed for turning/milling or milling/turning