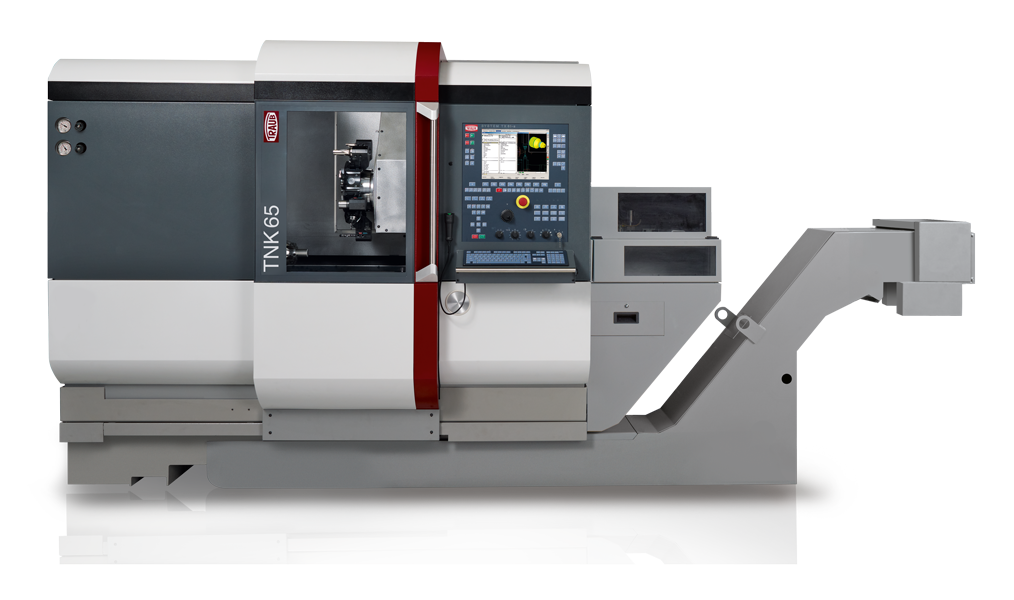

TNK-65 The efficient CNC fixed headstock turning machine

Dynamic rigidity and thermal stability for the highest precision of your turned parts.

-

Simultaneous machining with up to 3 tools

-

Easy change-over and handling by very good accessibility to the work area

-

Process reliability through vertical and clearly structured work area with large axis travels and generously sized tooling circles

-

Economic power density due to small erecting dimensions

-

Dual function of the lower X/Z slide:

Tool turret and swiveling counter spindle for rear end machining

The machine design

The main spindle

-

Highly dynamic motor spindle in synchronous design

-

Fast acting C-axis positioning for short cycle times

-

Liquid cooling supports the thermal stability of the machine

-

High spindle performance allows large cutting volume

The back working attachment

-

8 tool stations

-

5 of which are live tool stations (12,000 rpm and 6.7 kW)

-

Long travel distances of the counter spindle allow a large tool pool

Upper tool carrier

-

10 tool stations

-

Powerful tool drive on all stations

-

Long axis travels

-

Turret indexing designed as NC rotary axis (without mechanical interlock) allows any angle positioning and chip-to-chip times of 0.4 s (station to station)

-

Simple multiple tooling of tool stations

Counter spindle with lower tool carrier

-

Powerful counter spindle with large travel distances in the X- and Z-axes

-

Integrated tool turret with 9 stations

-

Fast C-axis positioning

Dual Drive (option)

The drive system in which the next tool is accelerated or decelerated during main time. Moderate acceleration and gentle deceleration ensure a long service life of the live tool holders. The Dual Drive system allows a tool change from live tool 1 to tool 2 in just 0.4 s chip-to-chip time