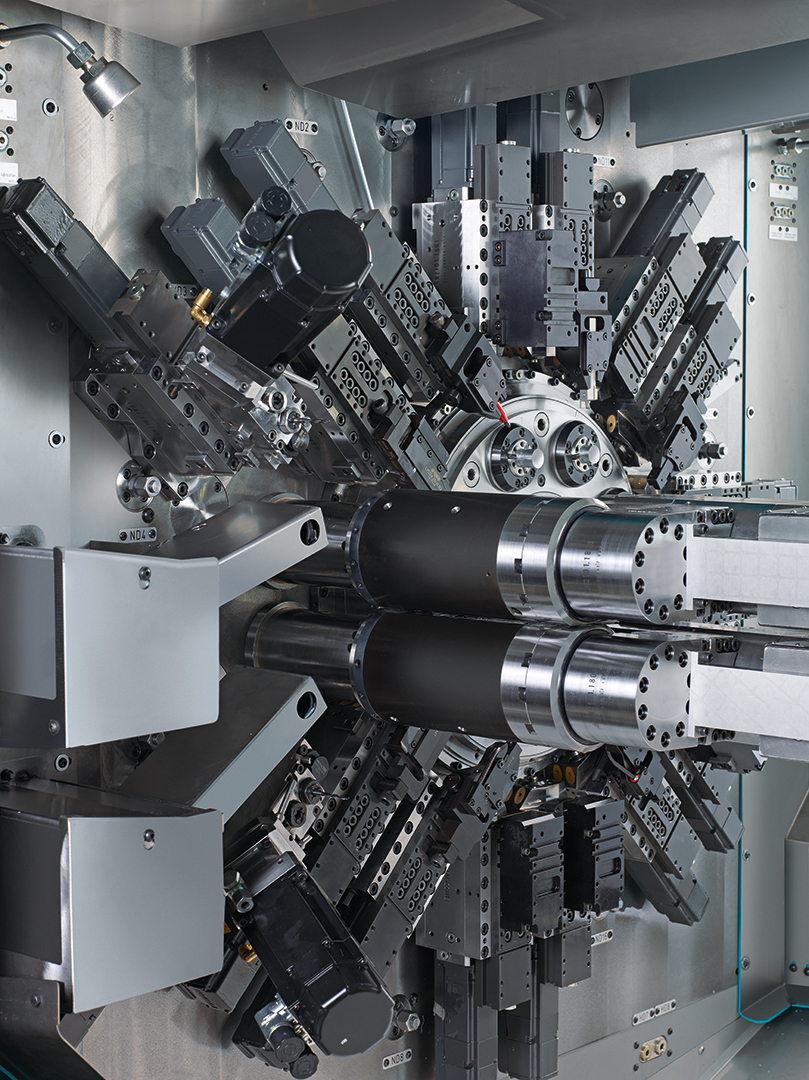

Productive multi-spindle machine with 8 spindles

8 main spindles, up to 2 swiveling synchronous spindles and up to 16 tool carriers.

Machine highlights

Your benefits

-

Highly-dynamic slides with sliding guide (X-axis)

-

Non-wearing Z-axis due to quills with hydrostatic support

-

Chuck part machining with loading and unloading by robots

-

Up to 16 tool holders with 1 or 2 axes and optional Y-axis can be used variably

-

Versatility is the strong point of the MS22C-8. Whether complex parts or different processes are involved – anything is possible

-

More options for rear end machining with hydraulically locked and extremely fast swiveling synchronous spindle

-

Already included: the operating systemXpanel i4.0 readywith 18.5” touch screen and INDEXC200-4D based on Siemens S840D sl

MS22C-8 in focus

The expansion options

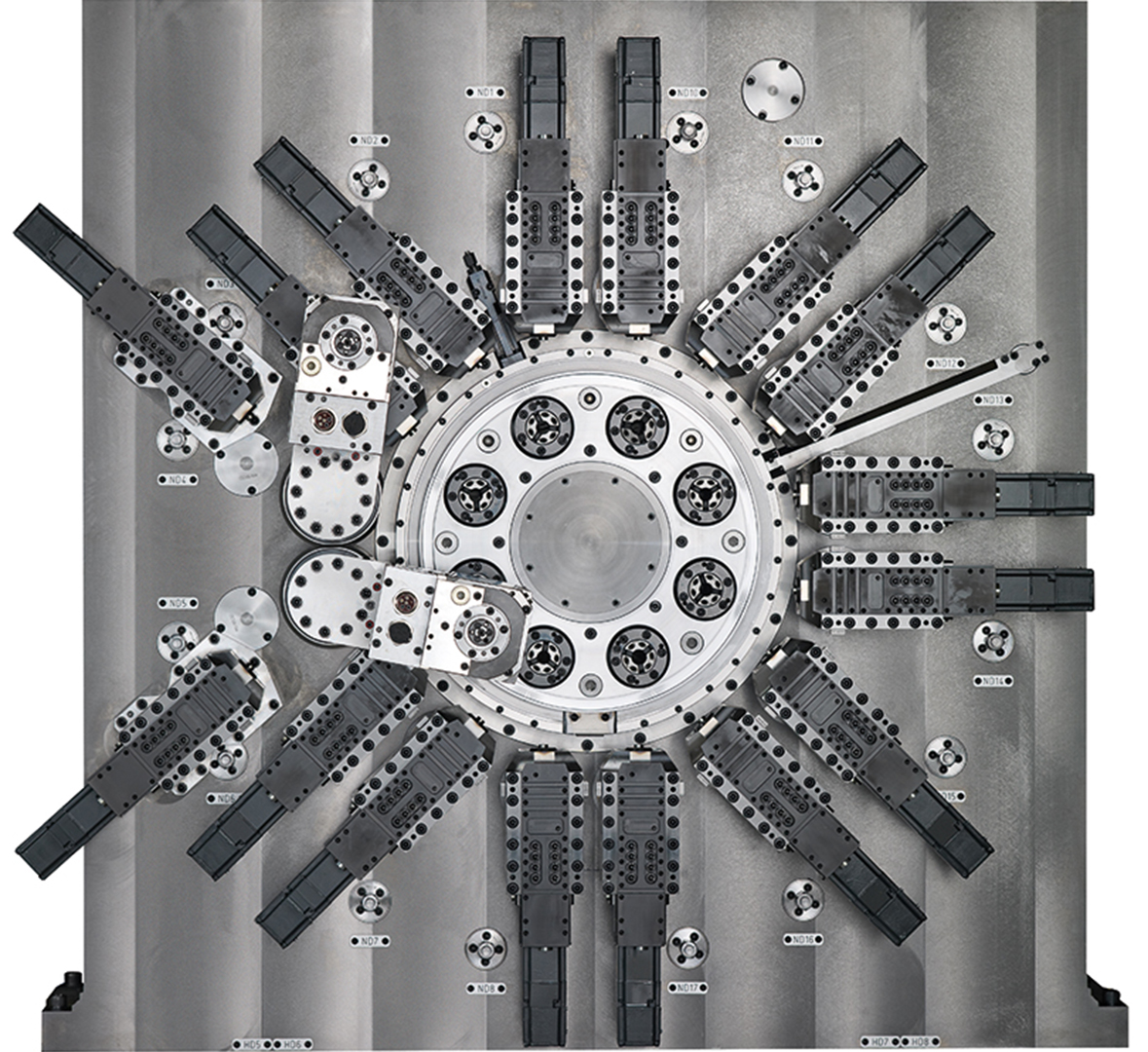

Double four-spindle machine – a profitable upgrade option

-

Additional part production time reduction due to simultaneous manufacturing of 2 workpieces

-

14 tool carriers with 1 or 2 axes (optionally also Y-axis)

-

2 swiveling synchronous spindles

-

2 rear slides (option) with 3 tools each, of which up to 2 are live

Your advantage:

Two identical or two different workpieces can be machined in parallel.

Result: fast cycle times.

Eight-spindle machining with simultaneous rear end machining

-

Front end machining with up to 15 X/Z tool carriers (optional Y-axis)

-

Cutoff end machining at the same time

-

1 swiveling synchronous spindle

-

1 rear slide

-

Versatile machining options

-

Machining of highly complex workpieces possible

Your advantage:

Reduced cycle time with time-determining rear end machining

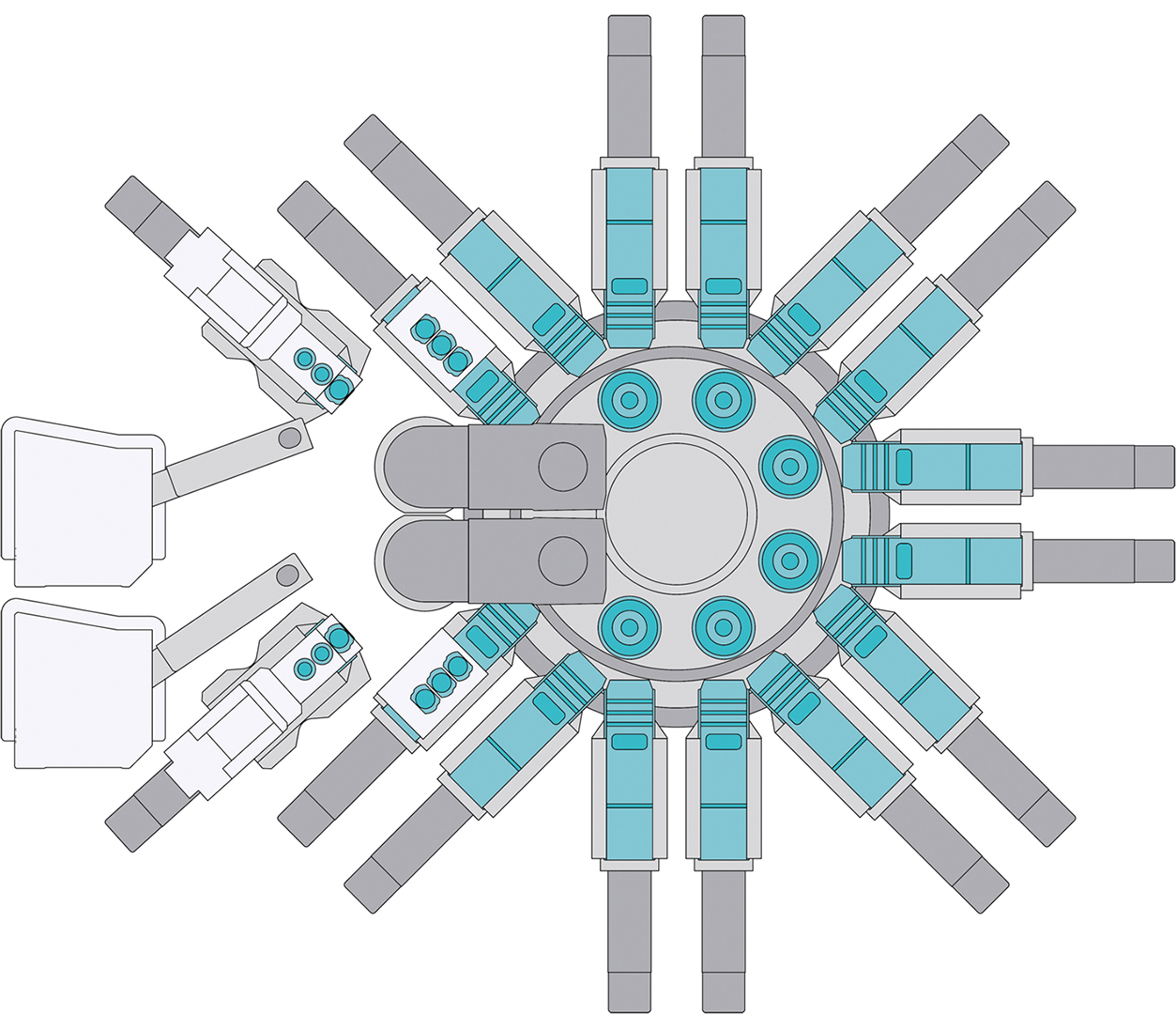

Pioneering multi-spindle technology

Explore the virtually limitless machining flexibility and the advantages of the INDEX MS22-8 multi-spindle turning automatic.

The adjacent animation shows you a wide variety of machining options on a multi-spindle machine.