Methods & Equipment offers the latest in Production CNC Lathes and can offer Full Turnkeys, Share Keys, or stand alone machines.

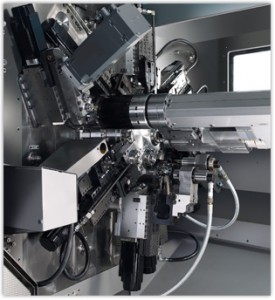

Multi- Spindles

Multi- Spindles

- Front-opening machine for bar machining

- Freely accessible and thus extremely user-friendly

- Highly-dynamic slides with sliding guide (X-axis)

- Non-wearing Z-axis due to quills with hydrostatic support

- Extremely fast synchronous spindles

- Maximum of 6 tools for rear end machining

- 6 or 8 Spindles

- Up to 52mm bar capacity

High Production Lathes

High Production Lathes

- Twin or Single Spindle Lathes with or without Gantry Loader

- Live Tooling Double Spindle w/ Y axis

- 3 Axis Gantry Loaders

- Fully automatic load/unload

- Twin Opposing Spindle Lathes for Shafts or Bar

- Learn More

Swiss Lathes

Swiss Lathes

-

Simultaneous machining with up to 3 tools (each tool with variable feed rate)

Clearly structured work area with large axis travels and wide tooling circles

Excellent accessibility through a large sliding cover

Easy changeover between sliding and fixed headstock operation

Very compact machine design with small footprint

Highest precision due to thermal symmetric machine structure

DualDrive: New tool drive system from TRAUB

High Production Lathes

High Production Lathes

- Vertical axis opposed electrospindles

- Compact rigid structure that incorporates mechanical and auxiliary components within a single unit

- Ergonomic architecture with very easy access to fixturing and tools for replacement

- Linear motors

- Modular layout with 2 to 6 spindles

- Fully automatic load/unload

- Flexible layout in terms of quantity and type of tooling with fixed tool holders or live tools

- To fulfill any turning requirement for small or average sized pieces.

- The synchronous spindle with C-axis allows working with the piece fixed or in interpolation.

- Learn More